Gold and silver lured many a prospector out to Death Valley and surrounding environs, but the mineral compound that proved most financially lucrative is common borax (Na2B4O7·10H2O). Borax is a concentrated soluble salt containing boron that was once collected from ancient lakebeds in Death Valley National Park.

Borates were first discovered in North America in Northern California’s Tehama County in 1856. Evaporated surface deposits of crude borax called tincal (Na2B4O7·5H2O) had been recognized in Death Valley and surrounding areas during the country’s first round of “borax fever” in the spring of 1873. However, the remote location, along with the lack of reliable transport necessary to ship it out of this formidable desert, kept it from being exploited. By the early 1880s, scores of borate prospectors began frequenting the Amargosa Valley and nearby lands, driven by rumors that a new rail transport line was in the works which could connect the Mojave Desert with shipping hubs near the coast. Recent borate discoveries bringing in profits in neighboring Nevada also drove the prospecting frenzy. Henry Spiller was one of many borax adventurers making his way southward across Nevada. On an opportune evening during the fall of 1881, he stopped at the Winters’ cabin for the night.

After dinner, Spiller exuberantly showed off a sample of “cotton ball” known as a surface formation of ulexite (NaCaB5O6(OH)6·5H2O) and one of a hundred or so related mineral ores containing borax. Spiller confided to his hosts that fortunes awaited those lucky enough to find a generous deposit of the stuff. He showed them how to test for the mineral’s presence with a combination of alcohol and sulfuric acid, which Aaron carefully noted. After Spiller left the next day, Aaron announced to Rosie that he had seen a material very similar to the one Spiller had described out on the desiccated lakebed of Death Valley.

That morning, the couple set off across the Funeral Range to Furnace Creek to collect samples of the dingy white bulbous material spread across the desert floor that resembled a handful of used cotton balls. At nightfall, back at their camp, “when the shadows had closed in around them, Winters put some of the salt into a saucer, poured the acid and alcohol on them and with trembling hand struck a match.”[1] Watching anxiously, Aaron exclaimed, “She burns green, Rosie! We’re rich, by God.” Winters staked his claim and immediately sold it for $20,000 in 1881 to William Tell Coleman, a Kentucky native turned San Francisco borax magnate who was known as a controversial iron-willed vigilante leader during the 1850s.[2]

Coleman’s Harmony Borax Works at Furnace Creek began processing cotton ball within months of his acquisition with a workforce of forty Chinese laborers who scraped the mineral from the harsh desert floor for a mere $1.50 per day.[3] When summer temperatures climbed above 120 degrees, processing had to be suspended—not to provide relief for the toiling men, but because the borax could not crystallize properly under such extreme conditions.[4] Coleman’s venture in Death Valley was short-lived—production ceased within a mere five years after he had shipped a million dollars of borax from the valley floor.

The demise of Coleman’s borax-built empire was attributed to a series of poor investments, including an ill-planned “raisin venture” in 1887 and also to overproduction, which caused the borax market to crash. Coleman died a broken man a few years later in 1893, but would be forever associated with colemanite (CaB3O4(OH)3·H2O), the harder quartz-like calcium borate ore discovered by Philander Lee and his companions at Furnace Creek Wash in 1882.

Coleman’s numerous holdings were sold in 1890 for half a million dollars to his business competitor/colleague Francis Marion “Borax” Smith, who would go on to amass—and also eventually lose—his own $20-million borax fortune that began with an 1872 claim he had staked out at Teal’s Marsh in western Nevada at age twenty-six. Smith had a monopoly on domestic borax production with his consolidated Pacific Coast Borax Company, holdings of which included the borate-rich colemanite mines at Calico in the Daggett Mining District, where principal production of the mineral had continued until 1907 after the Harmony Borax Works in Death Valley had closed in 1888.

Coleman began transporting borax with mule-driven wagon teams out of Death Valley in 1883. He wasn’t the first to do so—John Searles’ San Bernardino Borax Mining Company had already begun hauling borax over 175 miles beginning in 1873 from his borax claim on the Slate Range Playa (renamed Searles Lake) to San Pedro, California. Coleman’s route across the Mojave Desert commenced at Furnace Creek and ended some 162 miles due west at a railroad shipping spur in Mojave, California. It was here that the infamous “Twenty Mule Teams” became recognized for hauling two massive wooden wagons with their commanding seven-foot-high rear wheels. Each wagon bore over ten tons of processed borax; two fully loaded wagons with a full 1,200-gallon steel water tank and additional supplies weighed in at 36.5 tons. Over 10,000 tons of borax was carried out of Death Valley via mule teams between 1883 and 1889. In comparison, Rio Tinto’s open-pit U.S. Borax mine at Boron, California, today mines over 12,000 tons of industrial borates daily, providing nearly half of the world’s total supply.

It took ten grueling days across the searing desert to reach the town of Mojave. Every fourth day, a new team loaded with borax would disembark from the works between mid-September until mid-June. Two men were necessary to operate the rig: the driver, or skinner, who harnessed, maintained and drove the team while operating the brake of the lead wagon, plus the swamper, who minded the rear wagon’s brake and handled camp chores of gathering firewood, assisting with the animals, cooking and cleaning up after meals. The driver was paid $100 to $120 a month and the swamper received $75.

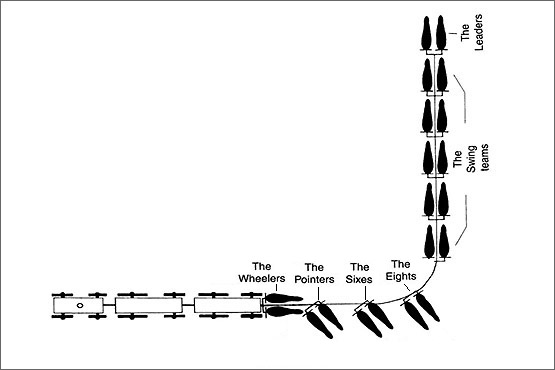

The “mule” team was technically two draft horses hitched at the wagon tongue with eighteen mules strung along a 120-foot long leather jerk line that ran through the animals’ harnesses up to the leaders of the team, selected for their intelligence and ability to lead the others. The skinner rode the nigh wheel or the first left-hand draft horse and operated the front wagon brake from this position. For an experienced driver, working a straight line was not much of a challenge, but navigating a curve was another story. Specialized sections of the team, which included two-mule pairings called pointers, sixes and eights were chosen and trained to undertake special tasks like jumping the chain connecting them to one another in order to angle their bodies while stepping sideways so that the preceding animals could make the curve. This technique was particularly important when negotiating a cliffside curve as the entire wagon train could fall off, driver and all. Although there were no reported accidents, breakdowns or animal casualties over the years of service, a driver was beaten to death with a shovel during a heated argument in October 1886 by his swamper. The defendant was later acquitted of the crime under self-defense.[5] By 1896, transport of borate ore would be shipped entirely by rail.

Through an ingenious advertising campaign popularizing the “lore and mystique” of Death Valley, these skinners became legendary. Stephen Tyng Mather, who worked early in his career for Pacific Coast Borax Company (later as the founding director of the National Park Service) was credited with coming up with the idea to promote the Twenty Mule Team as a brand. Smith initially balked at the idea, but came around, realizing its marketing potential. Personalities like feisty William “Borax Bill” Parkinson hadn’t actually hauled borax across the blistering Mojave Desert, but was instead hired and trained as a driver for the 1904 St. Louis Exposition and other promotional tour events across the U.S. William Frank Wilson followed Parkinson as the new “Borax Bill” after Parkinson’s sudden death.

A characterization of Borax Bill in an early twentieth-century brochure produced by Pacific Coast Borax Co. is as follows: “Bill understands every word of the mule language; talks to them in their own tongue and uses many expressions while handling these animals that would not sound well in polite society.” The text goes on to mention how he held copyright on a “large number of peculiar expressions” when dealing with the “balky mules.” The same promotion ends rather abruptly with the following statement: “Millions of pounds of Borax are used annually by the British government to preserve mild cured hams. The Borax is dusted on the flesh side of the ham.”

Boron in its pure crystalline form is a black silvery metalloid reigning fifth in the Periodic Table of Elements. It is listed only second in hardness on the Mohs scale to the carbon-based diamond. Boron is present in the oldest rocks on Earth, dating back 3.8 billion years, and unlike many elements created during fusion reactions within stars, boron formed after the Big Bang through the process known as cosmic ray spallation where “colliding cosmic rays split the nuclei of atoms, causing fission.”[6] Boron is essential for all living things, especially plant life, as it serves as a crucial micronutrient. In a 2009 New York Times article Stony Brook University geosciences researcher Artem Oganov noted how “Boron is a truly schizophrenic element. It’s an element of complete frustration. It doesn’t know what it wants to do. The outcome is something horribly complicated.”[7]

The human use of boron compounds is lengthy and diverse. It is believed that Babylonians first employed borax for goldsmithing more than four thousand years ago. Egyptians were said to utilize it for embalming mummies, metallurgy and pharmaceuticals. The Chinese were noted for their colorful third-century ceramic glazes containing borax. Texts mention how both Caligula and Nero may have sourced costly borax in the gladiatorial ring for an “extravagant” decorative effect or to “preserve the relics of the fight in all their ghastly reality.”[8] Archeologists confirm that Arabs had actively traded borax in small quantities along the Silk Road from its source in the Himalayas from at least the eighth century AD and possibly earlier. From antiquity until the present, crude, unrefined borax is referred to as tincal or tincar, which is derived from the Sanskrit word tincana. Borax’s more popular common name most likely evolved from the Arabic word baurach.[9]

Contemporary uses of borate compounds are equally varied. There are over fifty unique industrial and domestic applications for them. For instance, borates have been used since antiquity along with silica in frits used to form glass, enamels and ceramic glazes and also as metallurgy fluxes. Heat-resistant proprietary glassware such as Pyrex® is formed from borosilicate glass to resist shattering and thermal shock. Borate compounds are used to strengthen cellphone, computer and television LCD screens to keep them from warping under high temperatures. Fiberglass composites incorporate borates to ward off flame, water and chemical incursions while enhancing the material’s insulative qualities. Flame retardants contain borates to protect a variety of materials including wood, paper and other natural fibers such as cotton. Wood and cellulose products are treated with borax to make them resistant to fungus, ants, termites and other organisms. Borane, or boron hydride, a cousin of the boron family, has been used in rocket fuels due to its inherent chemical volatility.[10]

Additionally, borates are used in fertilizers, fiber optics, insulation fiberglass, semiconductors, water softeners, detergents, pH buffers, anticorrosive coatings, abrasives, batteries, magnets, antiseptics, insecticides, preservatives, cosmetics, electroplating, fuel additives, taxidermy and various home health remedies. In smaller gold mining operations, borates may be used as an alternative to mercury amalgamation for extracting gold. They additionally can absorb rogue neutrons during controlled or uncontrolled nuclear fission reactions.[11] Borate waste is the main liquid by-product of daily nuclear power plant operations. School children are taught to make a slime called “gak” or “flubber” from powdered borax mixed with Elmer’s glue as one of their first sensory science experiments. San Francisco-based artist Alexis Arnold has used a concentrated borax solution to grow crystal structures on discarded books, transforming them into miraculously stunning art objects that, in her own words, “have become artifacts or geologic specimens imbued with the history of time, use and nostalgia.”

By far the most well-known use of borax is through laundry boosters and soap products made famous by Smith’s 20 Mule Team Borax® brand, which has been in continual use under its original product name for 125 years, making it one of the most enduring trademark campaigns of the 20th century. The brand’s popularity coincided with a societal push towards cleanliness and germ eradication in both the U.S. and Europe. The “merits” of 20 Mule Team Borax® were first peddled to the general public in a series of advertising campaigns capitalizing on the product’s short but mythical extraction stint in Death Valley during the 1880s. Smith’s goal was to “put a box of borax in every home” and he mostly succeeded at doing just that. Indeed, the overwhelming popularity of this household product is credited with depleting the Calico deposits early in the twentieth century.

Besides being promoted as a laundry detergent, borax was touted as an essential personal health, hygiene and cosmetic aid. A 1919 trade pamphlet titled Borax: The Magic Crystal stated, “Perfect health depends on perfect hygienic cleanliness; and perfect sanitary cleanliness is secured by the use of nature’s greatest cleanser and most harmless antiseptic—Borax.” The pamphlet said that the product could remove freckles, be used as a sunscreen—or as a deodorant—and soften the hands that had done too much manual labor. The message that being clean—and paler—was the ticket to the American Dream was almost explicit in advertising of the time, which was aimed at a big melting pot of recent immigrants. As ad executive Albert Lasker told his staff in the 1920s, “We are making a homogenous people out of a nation of immigrants.”

In 1930, the company pulled off another trick by turning itself into not just a shared soap but a shared memory of bygone frontier days, producing a radio show called Death Valley Days, which was created and scripted by Ruth Woodman. The show’s distinctive lonely bugle call at the beginning of each segment drew its family-targeted audience to their radio in anticipation of another western morality tale introduced by the Old Ranger, the program’s regular character host.

After a lengthy fifteen-year run, the radio show ceased in 1945. The television version of Death Valley Days was first broadcast in 1952 and ran for some 600 episodes until it ended in 1975, making the show “one of the longest-running Western programs in broadcast history.” Hosts included actors Stanley Andrews (1952-63), Ronald Reagan (1964-65), Robert Taylor (1966-69) and others. Up and coming stars appearing on the show included Angie Dickinson, Clint Eastwood, James Caan and James Coburn. Country legend Merle Haggard recorded voice-over narrations in 1975 for some previously produced episodes.

Reagan, who had regularly hawked Boraxo powdered hand soap and their “waterless” hand cleaner during station breaks, did the final acting of his career on the show—he left before entering the race for governor of California, in 1966. One can only guess that his wholesome, squeaky-clean persona presented weekly on Death Valley Days helped him win the election and foreshadowed Reagan’s uncanny ability to evoke a mythic past with a vision of domestic tranquility for political purposes.[12]

Today borax is celebrated by many as an eco-friendly, non-toxic alternative for a variety of household purposes. Nevertheless, it has its detractors. As with any “green” product, consumers should scrutinize borax’s potential toxicity along with its advertised benefits and also consider the overall environmental footprint of extracting the mineral on such a grand scale.

The Kramer Deposit at Boron, California, is an eighteen-million-year-old, 200-foot deep subterranean lakebed spreading across hundreds of acres and considered “one of two world-class borate deposits on the planet.”[13] It is home to Rio Tinto Minerals—California’s largest open-pit mine, located three miles north of Boron, 130 miles north of Los Angeles. The original underground mine opened in 1927 after an enormous subterranean deposit of kernite (Na2B4O7·4H2O), also known as rasorite, was discovered the previous year. Kernite, named after Kern County where it is uniquely found, supplanted colemanite as the primary borate ore mined throughout the region.[14] More than 200 miles of tunnels were dug here before the mine was transformed into an open-pit operation in 1957. Today, the pit measures 1.75-miles wide and two-miles long with a depth of 755 feet.

The mine’s parent company, Rio Tinto Group, is a British-Australian multinational corporation originally formed in 1872 that now manages major metal and mining operations on five continents, including the former U.S. Borax (Smith’s original company), which it acquired in 1967. Rio Tinto sold 20 Mule Team Borax® and related product lines to Dial Corporation in 1988.

The company’s name derives from the Rio Tinto River in southeastern Spain, which has been mined for various minerals including copper, silver and gold since antiquity, causing the river to run continuously red with acid mine drainage, a hazardous pollutant that occurs when sulfide-bearing minerals are exposed to air and water. This phenomenon is often found in surface streams near past or current mining areas where it can kill or disrupt growth and reproduction of fish, aquatic plants and animals, contaminate drinking-water sources and corrode nearby infrastructure.

Although Rio Tinto Group has received praise for its sustainability and environmental stewardship practices worldwide, the company also has also been criticized by major news organizations and various nonprofit corporate watchdog groups. Rio Tinto’s Boron facility is largely considered environmentally sustainable, but management has previously received poor marks for labor relations, including a controversial lockout of more than 500 unionized workers in 2010 when management balked at proposed contract concessions with the International Longshore and Warehouse Union. A new six-year contract negotiated within three months of the start of the lockout ended the dispute.

The museum at the Borax Visitor Center and at Rio Tinto’s Boron mine is free to the public. While in Death Valley National Park, be sure to check out The Borax Museum at Furnace Creek. This article is co-published with KCET Artbound. Visit Artbound’s Mojave Project page here.

Did you enjoy reading this dispatch? Consider supporting us with your tax-deductible donation.

Click here to learn more.

FOOTNOTES (click to open/close)

[1] Richard E. Lingenfelter, Death Valley and the Amargosa: A Land of Illusion (Berkeley: University of California Press, 1986), 174.

[2] Aaron Winters purchased a large ranch in Pahrump, Nevada, in May 1882 with most of the money gained from his sale to Coleman. Not long after, his wife Rosie died. By 1887, he had lost most of the property due to his failure to pay back taxes.

[3] The amount of $1.50 was a decent wage for the 1880s if you consider that “mucker” wages during the 1910s were $1.75 at Pacific Coast’s Lila C. borax mine. Still, Chinese workers paid most of this back to the company for overpriced supplies and food at the company store.

[4] Other independent borax mining and refining facilities, including Eagle Borax Works, existed in Death Valley simultaneously, but Coleman’s monopoly controlled the majority of its production and shipment during the 1880s. For further reading see Death Valley and the Amargosa, 178-179.

[5] Lingenfelter, Death Valley and the Amargosa, 184.

[6] Stephanie Pappas, “Facts About Boron,” LiveScience, TechMedia Network, 2014, https://www.livescience.com/28674-boron.html.

[7] Kenneth Chang, “Theory and Experiment Meet, and a New Form of Boron Is Found,” New York Times, February 2, 2009.

[8] John R. Spears, Illustrated Sketches of Death Valley and Other Borax Deserts of the Pacific Coast (Chicago: McNally & Co. Publishers, Vol. 1, No. 175, 1892), 212.

[9] Jaime Wisniak, “Borax, Boric acid, and Boron—from exotic to commodity,” Indian Journal of Chemical Technology 12 (July 2005): 488.

[10] Dave Shubert, “From Missiles to Medicine,” Borax Pioneer Magazine, March 1, 2001.

[11] Russians poured some 6,000 tons of boric acid and sand on Chernobyl Reactor #4 in an effort to control the meltdown disaster that took place on April 26, 1986.

[12] Reagan became governor of California in 1967. Following a complaint during the campaign by sitting Governor Pat Brown, California television stations dropped Death Valley Days to conform to the equal time ruling.

[13] The largest known borate deposits in the world are located in Turkey. Commercial borate ores are also found and mined in Chile, Bolivia, Tibet and Romania.

[14] Dr. John K. Suckow discovered the initial deposit of colemanite while drilling for water for his Boron area ranch in 1913.